VR and Construction Safety Training

The emergence of virtual reality programs is taking safety training in construction to new levels.

Construction work typically takes place in hazardous outdoor settings, in all kinds of weather, and often at height. So, it’s no surprise that the industry always ranks near the top in workplace fatalities. This makes safety training a critical priority for the building trades.

Simple decency demands that employers provide comprehensive safety training for their workers. There is also a strong monetary incentive; accidents slow down work schedules and lead to fines, lawsuits, and higher insurance premiums. If that weren’t enough motivation, the Occupational Safety and Health Administration (OSHA) requires specific safety training protocols for construction workers and threatens noncompliant employers with substantial fines.

Traditional safety training, while important and informative, also has a downside: It can be boring. People who entered the field to be carpenters or crane operators can find themselves staring at computer screens or sitting in classrooms. Their safety training can be something they simply endure until they can get back to the job. And it doesn’t matter how relevant the content is if the trainee doesn’t retain it.

That’s the backdrop for a revolutionary new development: the use of virtual reality (VR) in safety training programs.

Virtual Reality Finds Its Niche

Since the emergence of virtual reality technology in the last century, it has found a variety of uses, most notably as a training tool for pilots, military, and medical professionals. Its popularity as a gaming device for consumers initially showed great promise but has waned recently, probably due to the high cost of VR equipment.

However, the effectiveness of VR as an instructional platform made it a natural fit for industrial training courses, such as those required for construction workers. VR uses sophisticated 3-D programs similar to those found in today’s computer games. The user dons a head-mounted device (HMD) and is immersed in a complete, simulated environment. The user is prompted to respond spontaneously to a series of challenges. Through the use of a motion controller or similar device, those responses are represented in the virtual environment in real time.

VR and the Construction Industry

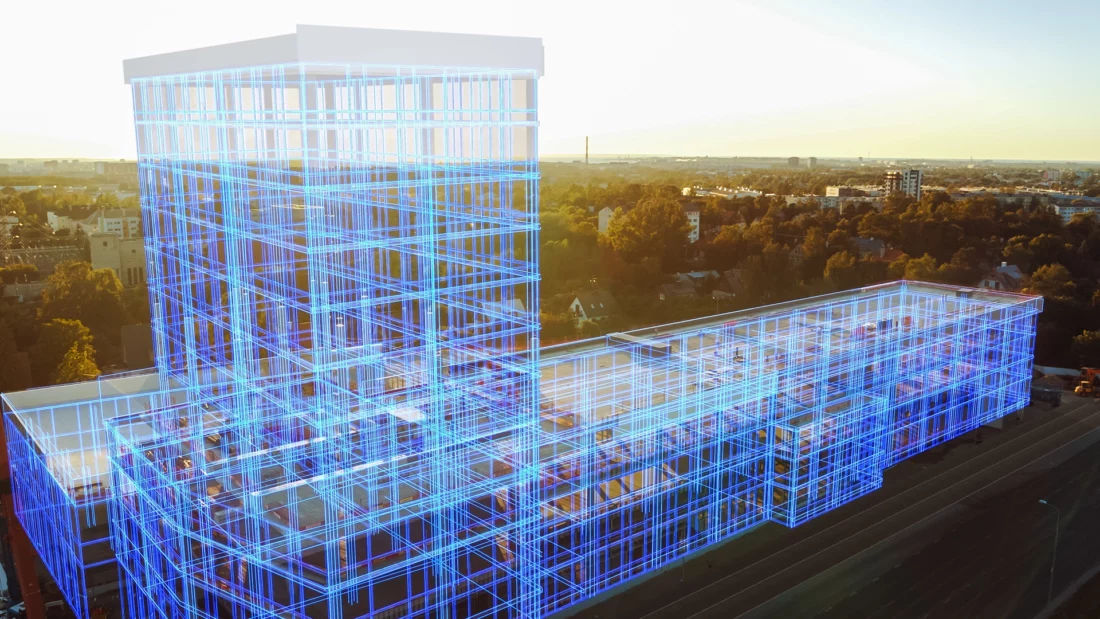

For construction uses, a VR training program can present a digital twin of a jobsite that contains all the elements of the real thing. The user can become familiar with the construction site’s geography, identify potential hazards, learn to operate safety equipment, participate in emergency response drills, join interactive safety workshops, and respond to a variety of hazardous situations—all virtually. A properly designed course can sharpen the user’s reflexes and reinforce desired behaviors. Performance can be tracked and scored, and the course can be repeated indefinitely until success is achieved.

Traditional safety training takes place in the field as well as the classroom. That implies certain risks as well as costs. Trainees may not operate equipment correctly, which can lead to damage or injury. They’ll be subject to all the physical hazards common to a construction site. And taking time to travel to the site and prepare for training also incurs costs. By substituting VR for some on-location training, those problems can be mitigated or eliminated. In a virtual environment, there is no damage to real equipment or property, the participant is not at risk of physical harm, and travel expenses are reduced, since the training can be made accessible anywhere.

As this approach has taken hold across the industry, VR providers report higher retention rates among trainees as compared with traditional training. Most people learn visually and by practicing; VR incorporates both approaches, making it especially effective.

Making VR Work for Construction

There are now numerous companies offering VR safety training for construction workers. Their courses cover topics such as fire prevention, fire suppression, fall safety, forklift operation, how to deal with downed power lines, and how to navigate confined spaces. Some providers combine VR with traditional training to vary the experience and present a well-rounded program. Providers that specialize in creating VR training environments include PIXO, Strivr, InsiteVR, Serious Labs, and 3M Safety Training VR.

In the past, the cost of virtual reality equipment put it out of reach for some smaller operations. But as with most new technology, prices can be expected to go down over time. Once the purchase is made, it can serve any number of trainees virtually indefinitely—eliminating the cost of an in-person trainer or seminar leader, not to mention the cost of equipment and printed materials. Thus, the purchase of VR training programs can be a reasonable long-term investment. Some providers also offer a rental option now, making VR training more universally accessible.

As with virtually every other phase of the construction process, new technology is leading to safer, cheaper, more efficient safety training. It’s clear that virtual reality safety training isn’t just a vision for the future. It’s here, and it’s working.